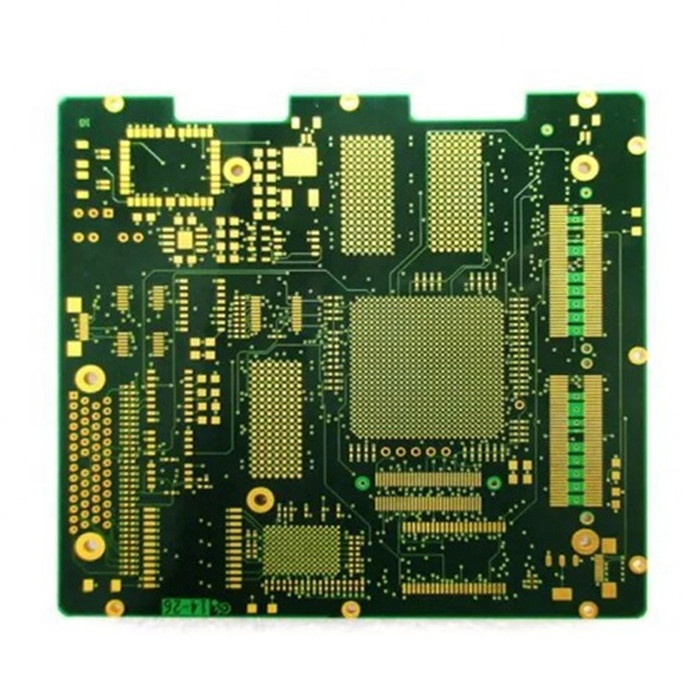

FR4 CEM1 CEM3 Multilayer Printed Circuit Board One Stop OEM Service

About us:

Was founded in year of 2010 .With being OEM manufacturer

specializing in PCB/PCBA Sensors etc with 11-year,nowadays,we have

built up our strong product research and development center and we

are devoting ourselves to electronics smart product. combined with

the wealth of experience and expertise we have built up over the

years, means we can offer a total solution to our customers one

stop Service

requirements – from front end engineering through to in time

deliveries.

Our PCBA Capability

SMT, PTH, mixed technology

SMT: 2,000,000 solder joints per day

DIP: 300,000 joints per day

Ultra fine pitch, QFP, BGA, μBGA, CBGA

Advanced SMT assembly

Automated insertion of PTH (axial, radial, dip)

Cleanable, aqueous and lead-free processing

RF manufacturing expertise

Peripheral process capabilities

Pressfit back planes & mid planes

Device programming

Automated conformal coating

For E-Test

Universal Tester

Flying Probe Open/Short Tester

High power Microscope

Solder ability Testing Kit

Peel Strength tester

High Volt Open & Short tester

Cross Section Molding Kit With Polisher

Model Number: | ZYX-217XCDSQWW | Place of Origin: | Shenzhen, China |

Brand Name: | QBZYX+ | Base Material: | FR-4/CEM-1/CEM-3/Polyimild/PTFE/Rogers |

Copper Thickness: | 0.3- 6 OZ | Board Thickness: | 0.3 mm- 4 mm |

Min. Hole Size: | 0.2 mm | Min. Line Width: | 0.1 mm |

Number of Layer: | 1- 20 Layer | Silkscreen color: | Black, White, Red, Green |

Range of TG: | 130 - 215 ℃ | Service: | One-Stop OEM Service |

ZYX is a professional OEM manufacturer for PCB design, PCB

production, component souring and SMT assembly, we sincerely would

like to be your reliable OEM supplier from China.

With more than 11 years experience in the PCB industry, our

services

includes:

- PCB&PCBA Contract Manufacturing

- Reverse Engineering Services

- PCB Design and Assembly

- Component Procurement & Material Management

- Product Design

- Fast PCB&PCBA Prototyping

- Cable and Wire Assemblies

- Plastics and Molds

- AOI,X-Ray Testing, other Function Testing Service

Products Description

Item | Capability | Details |

Layer | 1-8 layer | 1-8 copper layers PCB (Don't support Blind/Buried Vias) |

Controlled Impedance PCB | 4 and 6 layer | No extra charge and only accept our default layer stack-up |

Material | FR-4 | ALUMINIUM and FR-4 |

Max Size | 60*50cm | Max size is 60*50cm |

Solder Mask | LPI | green/blue/red/yellow/black, etc. |

Finished Outer Layer Copper | 1oz~2oz(35um~70um) | Finished outer layer copper is 1-2oz |

Dimension Tolerance (Outline) | ±0.15mm | Dimension tolerance(outline) is 0.15mm |

Thickness | 0.4~2.4mm | 0.4/0.6/0.8/1.0/1.2/1.6/2.0/2.4mm |

Thickness Tolerance (T≥1.0mm) | ±10% | eg: For the 1.6mm board thickness, the finished board thickess

ranges from 1.44mm(T-1.6*10%) to 1.76mm(T-1.6*10%) |

Thickness Tolerance (T<1.0mm) | ±0.1mm | 0.7mm (T-0.1)~0.9mm (T+0.1) |

Drill Holes Size | 0.25~6.3mm | Min drill size is 0.2mm, Max drill size is 6.3mm |

Hole Size Tolerance | ±0.08mm | eg: For the 0.6mm hole, the finished hole size between 0.52mm to

0.68mm is acceptable |

Min. Trace | 3.5mil | For single&Double layer PCB,the minimum trace width is 5mil,For

multi layer PCB, The minimum trace width is 3.5mil |

Min. Spacing | 4mil | For single&Double layer PCB,the minimum spacing is 5mil,For

multi layer PCB, The minimum spacing is 4mil |

Min. Via diameter | Min Inner Diameter(Hole):0.25mm,Min outer diameter:0.5mm | For multilayer pcb, min inner diameter(hole)0.25mm.min outer

diameter:0.5mm For double layer PCB, min inner diameter :0.3mm, min

outer diameter :0.6mm |

Pad to trace | 6mil | Minimum distance betwen and trace is 6mil |

MIn. Character Width and heigh | Min character width:4mil, Min character height:27.5mil | Character width less than 4mil(0.153mm)will be

unidentifiable,Characters height less than 32mill be unidentiable |

Trace to outline(Ship as individual board with Rounting) | ≥0.2mm | Ship as individual board(Rounting):Trace to outline ≥0.2mm; Ship as

panel with V-scoring: Trace to outline ≥0.4mm; |

Trace to outline(Ship as panel with V-scoring) | ≥0.4mm | Ship as panel with V-scoring: Trace to outline ≥0.4mm; |

Min Strip | 3mm |

|

Panelization with space | 1.6mm | Make sure the space between boards should be≥1.6mm,otherwise it

will be hard to process for rounting |

Min.Half Hole Diameter | 0.8mm | Half hole is a special technology, so half hole diamter should be

bigger than 0.6mm |

Solder mask opening | 0.05mm | If need solder mask bridge , it should be more than 4mil. |

NOTE1:Copper hatching with software Pads | Hatching | We will supply Copper Hatching if your PCB designed with software

Pads,Pls refer to the picture. |

NOTE2:Slots designed with software Pads) | Outline | Please use outline to design if there are many

non-plated(NPTH)holes |

FAQ

Q. What service can you supply ?

ZYX are OEM PCB and PCBA manufacturer since 2010 ,we can provide

turnkey solutionincluding RD PCB fabrication,SMT and assembly PCBA

inside the enclosure,Functiontesting and other value-added service.

Q. What file you need to prepare if you want to get an quotation

from us?

For PCB board, you need to prepare files of Gerber file,it should

including RS-274X,ODB++, DXF, PCB, PCBDOC etc formats.

For PCBA(PCB with soldered components), except the file for PCB,

you also need to prepare the BOM list (components list), Pick and

Place file(txt format), real sample pictureor 3D PDF version file

etc.

Q. Do you have any MOQ Limited ?

We havent any limited about MOQ .Sample and mass production all can

support.

Q. How to keep our product information and design file secret ?

We are willing to sign a NDA effect by customers side local law and

promising tokeep customers data in high confidential level.

Q. How long does it take for PCB and PCBA Quote ?

PCBs quotation within 2 hours can finished the PCBA depend on the

components

quantity,if simple, within 6 hours can finished,once complex and

more,the 12- 36 hours

can be finished.

*Please note that the following detail will speed up evaluation:

Material:

Board thickness:

Copper thickness:

Surface finish:

Solder mask color:

Silkscreen color:

Q. How about the delivery?

Normally, for sample order, our delivery is about 5 days.For small

batch, our delivery is about 7 days.

For mass production batch, our delivery is about 10 days.

But that depends on the real condition when we get your order.

If your order is urgently please contact us directly ,we will

priority to deal it and do ourbest to give you satisfied delivery

time.

Q. How can we guarantee you receive an good quality product?

For PCB, we will use Flying Probe Test, E-test etc. for it.

For PCBA, we need you to offer us a method or test fixture for the

function test.Before that, our inspectors will use microscope and

X-ray to check the IC footwelding or bad solder etc.

Q. With payment terms do we acc